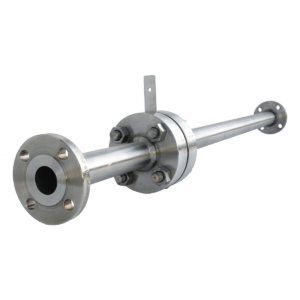

Description

Due to the tapered inlet and divergent exit venturi tubes are particularly suited to applications where pressure loss needs to be kept to a minimum for differential pressure flow measurement devices. This is due to the high degree of pressure recovery experienced with a venturi. The venturi is also suited to dirty flow applications as the contoured sections encourage the particles to pass through rather than build up. They are the costliest of differential flow products, but much shorter upstream piping straight length requirements and low running costs offset the initial outlay and make them extremely viable. They also have the added advantage of a flow nozzle with low susceptibility to erosion. Typical accuracy ranges between ±1% and ±2% for uncalibrated full-scale flow measurement which can be improved upon if calibrated. There are three styles of ASME venturi tube; ‘as-cast’ convergent section, machined convergent section and rough welded convergent section. AVCO supplies the machined and rough welded versions with all pressure taps pre-installed and geometry meeting ASME MFC-3M.