Description

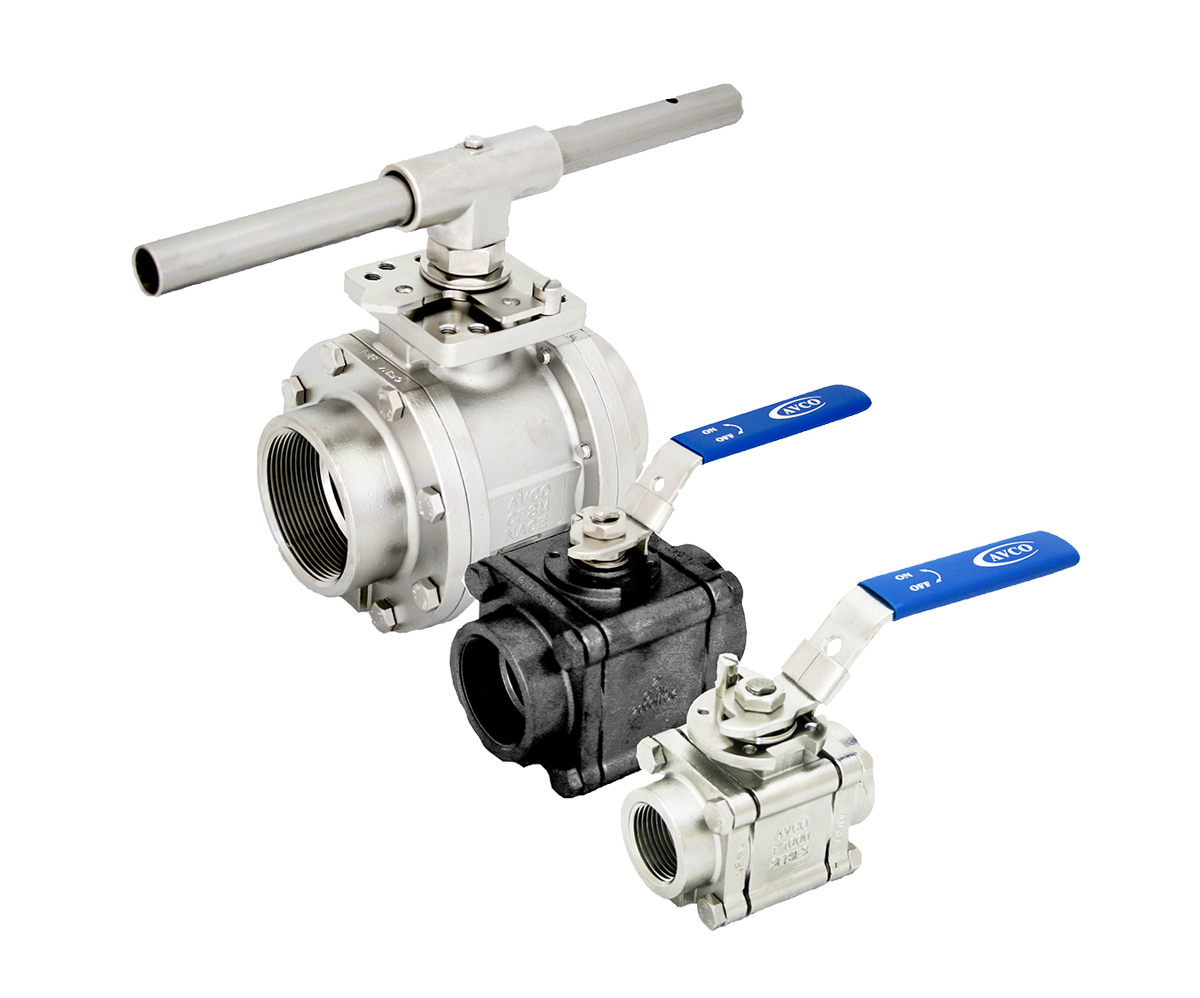

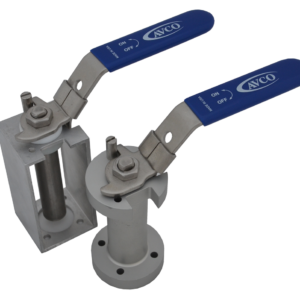

The AVCO Metal Seated ball valves are a variation of the AVCO 1000 Series 3- piece ball valves that are designed to provide a rugged and reliable solution for high temperatures or abrasive media applications. Starting with the standard components of the AVCO 1100 Series, it is adapted to accept precision machined Stellite 6 Metal seats. A hardened and lapped, high-tolerance 316SS ball and 17-4SS stem replace the standard balls, retainer rings and stems to enable the valve to operate in harsh conditions that the normal 316SS and plastic elastomer components cannot handle. Another AVCO advantage is that the metal seats are not matched to the ball. This means you can repair the valve in the field by replacing the ball or seats independently of each other and the valve will operate smoothly and reliably while still attaining up to an ANSI class VI shut-off. Metal seated valves are available with 316SS (CF8M) or carbon steel (WBC) bodies and ends. A variety of ends are available including butt weld, socket weld, NPT, BSP and flanged ends up to ANSI class 600. Options for the metal seated valves include using a v-port ball to create a control valve or a third port to create a diverting or mixing valve. Metal seated valves have higher torque than valves with plastic elastomer seats. The ISO 5211 mount pad allows for easy mounting of gear operators or actuators. As a safety feature, extended mounting brackets are available to provide additional distance between a heated valve and the operator. Whether for use in the oil, gas, chemical or steam industry; this valve will deliver performance, quality and ease of use in the harshest conditions.