Description

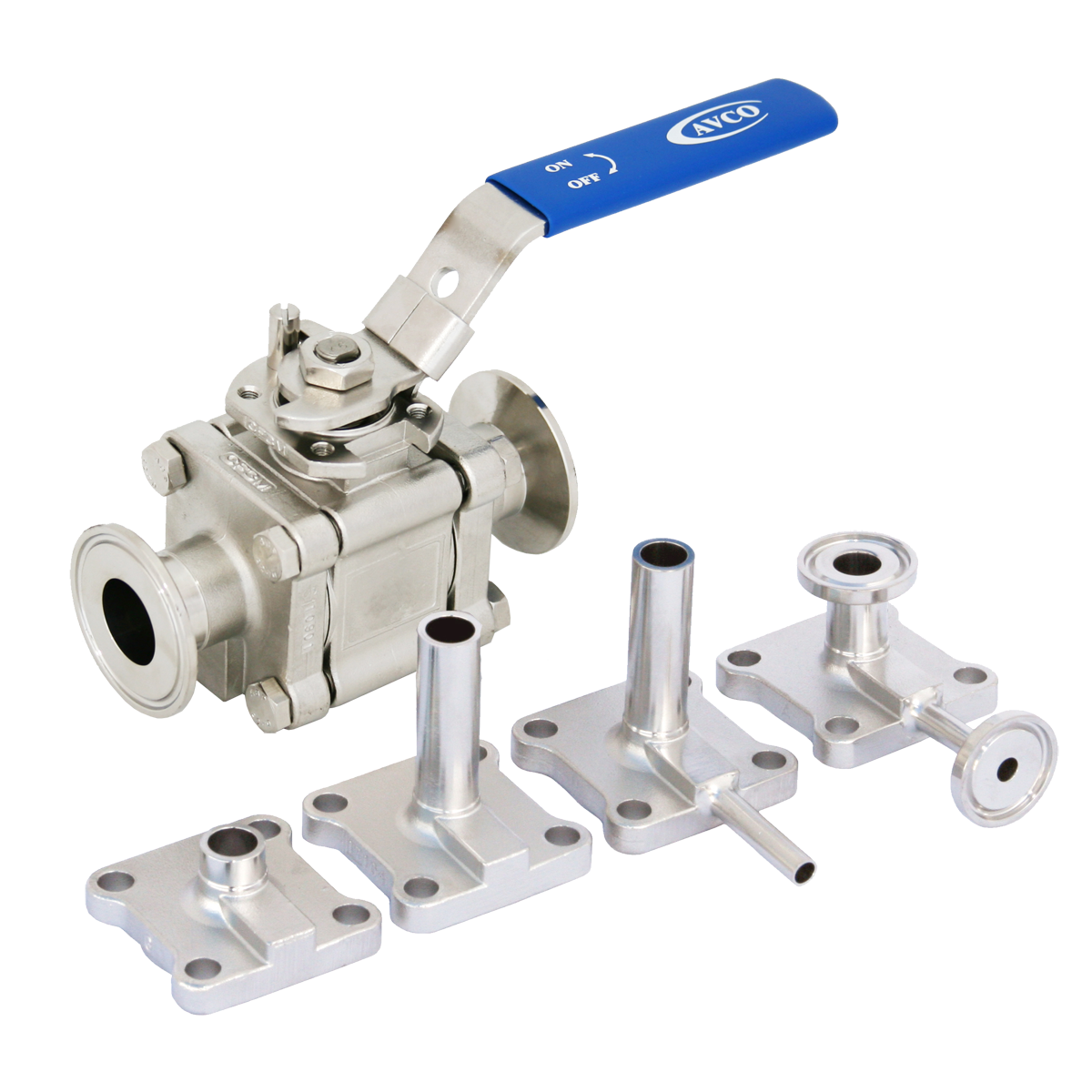

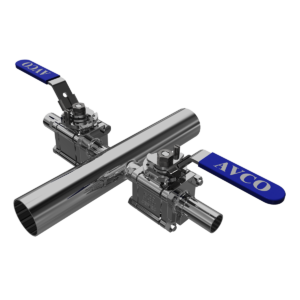

The AVCO 2100 series ball valve is a sanitary/clean valve ideal for use in the biotech, pharmaceutical and high purity industries. The 3-piece design comprises low carbon stainless steel (SS 316L) components, which come standard with 20 Ra surface finish on all contact surfaces and can be electro-polished to 15 Ra when required. Cavity filled seats are available to minimize dead space in the body cavity and keep operating torque low. We also offer FDA CFR177 approved seat and seal materials. End styles include regular or extended tube OD (suitable for butt weld), socket weld tube OD, clamp end, flush bottom tank pad, AVCO-Lok (compression fittings) and Vacuum Ends. All styles can be supplied with flushing ports to facilitate in-line cleaning (CIP & SIP) and reduce the need for plant shutdowns. Due to the requirement for cleanliness, these valves are all offered oxygen (O2) cleaned and bagged. The valves meet the requirements of ASME BPE as standard and are strictly controlled by our in-house QA procedures and come complete with an ISO 5211 mount pad for additional equipment to be installed. The 2100 Series valves are well suited for sanitary installations in the pharmaceutical, food & beverage and semi-conductor industries.